OKLm

Application

- Cable is designed for installation in cable duct, pipes, collectors, tunnels.

- OKLm cable with flame retardant protective jacket is designed for installation according to exclusive standards of fire safety.

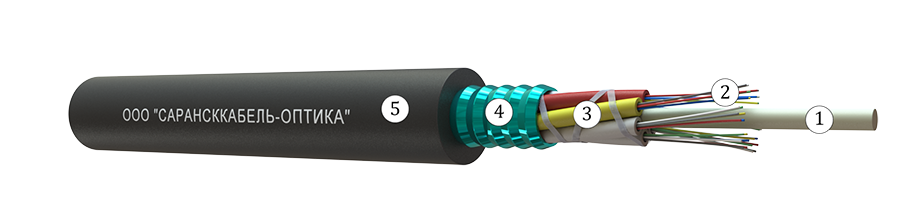

- Central strength member – fiberglass reinforced plastic rod

- Optical fiber

- SZ stranded loose tubes filled with hydrophobic gel

- Corrugated steel tape armor

- Protective jacket

(8342) 473-813, 480-299

| Number of fibers | |||||

|---|---|---|---|---|---|

| Nominal overall diameter, mm | |||||

| Total mass of cable with polyethylene jacket, kg/km ** |

** total mass of the cable with flame retardant protective jacket is specified when ordering

- Yellow tube - main.

- Red tube - guide.

- Natural tubes - counting from the red tube.

- • Black fillers are made of polyethylene.

By the customer’s request the color scheme may be changed.

| Temperature range of operation, С° | |

| Temperature range of installation, С° | |

| Minimal bending radius | |

| Lifetime | |

| Guarantee exploitation | |

| Tensile strength | |

| Crush strength |

** In case of cable with flame retardant protective jacket, the min. installation temperature is not lower than -10 °С.